Wood only – the history of Finnish wood construction

Livady Architects

Finland is a country covered by forests, and wood is a traditional Finnish construction material. Laura Berger and Netta Böök, researchers of the history of architecture and experts in the tradition of wood construction, explain how wood construction has transformed from a basic everyday skill mastered by all to industrial innovations and state-level export efforts.

“Are there pines and spruces in the southern lands as we do in Finland? There are fruit trees there, that much we know, but how about our beautiful spruces and pines, those probably don’t exist over there. We use them to build rooms, churches, firewood.” A schoolboy said: “What makes you ask such crazy questions? Don’t you know it’s so warm there in the south that they don’t need any rooms or firewood there?”

– Varpunen magazine, 1 June 1860

This discussion among schoolboys from 1860 makes visible the fact that traditionally all Finnish buildings, from homes to prominent buildings such as churches, have been constructed of wood. A traditional building is constructed of massive logs and equipped with a large oven. This is a matter of survival: a house with heat-retaining structures allows its residents to survive the long and cold winter.

Ever since the 1500s, the state had been encouraging Finns to construct buildings out of stone for aesthetic and fire safety reasons, with poor results. For a long time, domestic wood was practically a free construction material, and its relative softness made it easy to work with. In traditional Finnish peasant houses, wood was even used as a roofing material.

Constructing with logs is, however, a strenuous craft that consumes a lot of time and wood; optimally, a log used for building a wall is, at the maximum, 10–12 metres long and weighs hundreds of kilograms. Trees used for construction should also be over a hundred years old when felled if the intention is to use logs that best resist rot. Nevertheless, up until the early 1900s, Finns used wood for constructing everything from manor houses to schools and from barns to fire stations. Technically, log construction reached its zenith in the massive churches of the 19th century.

On the other hand, the log has been considered an ordinary material and, thus, has often been hidden behind boards or paint and wallpaper. In the 19th and 20th centuries, Finnish artists became inspired by the qualities of bare timber that they, in the national spirit of the time, associated with true Finnishness. Accordingly, they designed or commissioned cottages that were built with bare logs in the wilderness.

More with less

As Finland began its urbanisation process in the 1900s, a shortage of housing and cramped dwellings emerged as topical issues. A shortage of high-quality logs had already begun in the previous century, and now, more efficient, faster and less expensive wood construction methods were urgently required. Above all, three measures were introduced to improve the efficiency of building production: industrial construction, standardisation and lighter structures.

Finnish architects followed international development with great intrigue, particularly setting their sights on other Nordic countries and North America. One topic of interest was the lightweight balloon frame developed in Chicago, of which a version was created in Finland. Instead of logs, buildings were now constructed of cut-to-size sawn timber, which was nailed and reinforced with bevel siding. This construction method was enabled by the production of sawn timber at the industrial scale and standardised products, such as nails. The method consumed considerably less wood and made construction faster and more inexpensive.

In Finland’s cold climate, the balloon frame, however, became a competitive solution only in the 1930s, as new insulation materials were introduced to the market. At the same time, the modern movement shaped the stylistic ideals towards a more minimalistic direction.

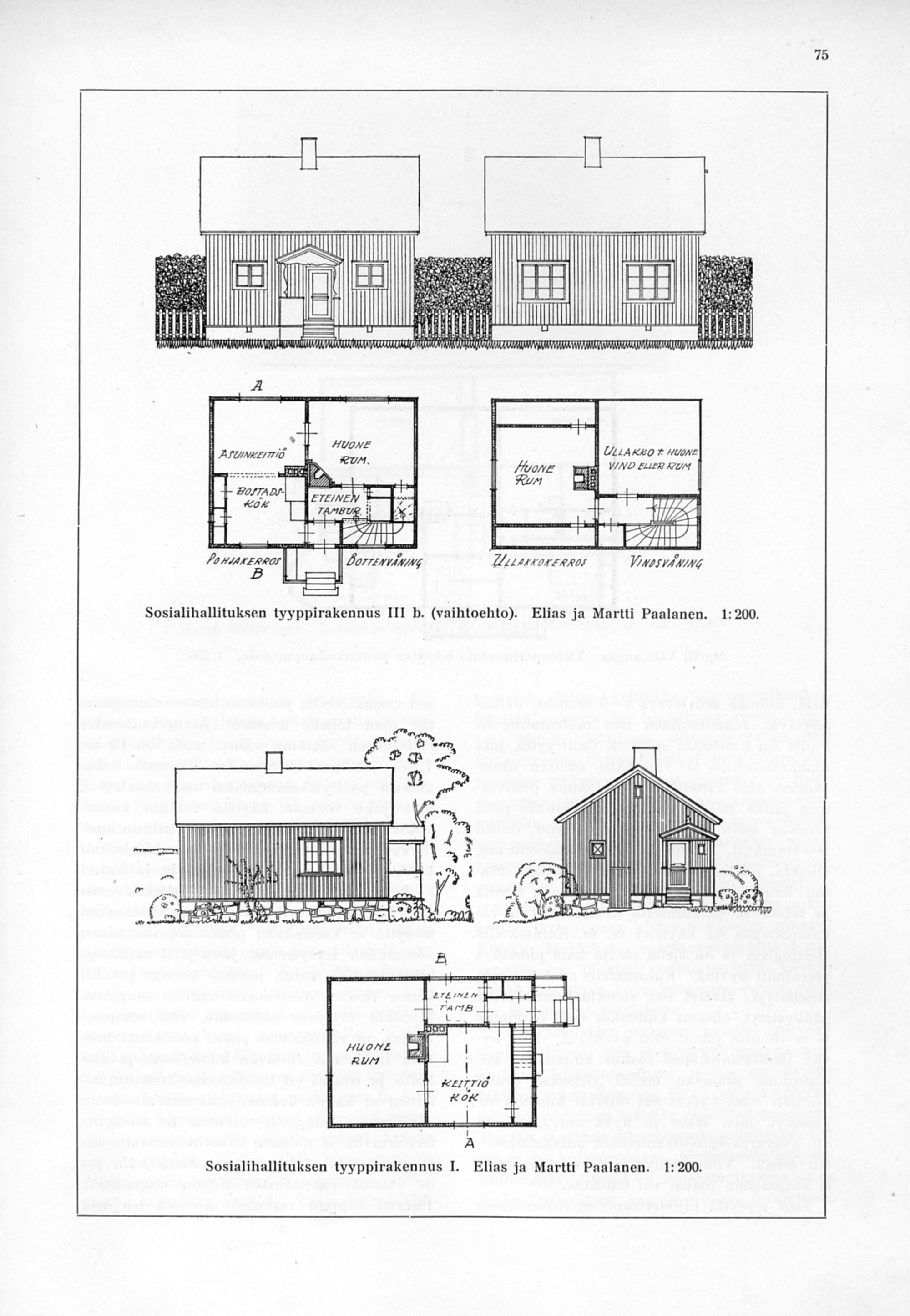

Standardised buildings served as a significant solution for enhancing the effectiveness of construction and estimating the required materials in advance. In the 1920s, the state and non-profit organisations, in particular, commissioned standard-project drawings for rural and semi-urban areas. The aim was to raise the quality of housing and to guide builders to create aesthetically pleasing buildings with a stylistically unified appearance.

In addition to the increased prevalence of standard-project drawings, many companies also began producing standardised houses in the 1930s. The aim was to utilise industrial prefabrication and standardisation in speeding up construction. An early example of this are the “A-talo” houses designed by Alvar Aalto in 1936 for the A. Ahlström company. Despite their well-known architect, only a rather small number of the houses were ever built, most of them as workers’ dwellings in forest industry areas.

While wood has been historically utilised for multiple purposes, industrialisation provided even more new opportunities for this. In the same year, Alvar Aalto was invited to London to organise an exhibition called “Wood only”. In addition to furniture, plywood objects, wallpapers, children’s wooden building blocks and, as a curiosity, a “fake silk” rug woven out of waste originating from cellulose, in other words, wood-based material, were presented at the exhibition.

Breakthrough in light wood construction

The Second World War caused an unparalleled need to quickly produce dwellings in rural areas and cities alike. In Finland, the question of housing became fervently critical in 1940, as Finland lost around ten per cent of its territory to the Soviet Union and faced the task of quickly providing dwellings to over 420,000 evacuees.

Although small numbers of prefabricated buildings had already been produced before, Puutalo Oy [Timber Houses Ltd.], established in 1940, was the first company to begin large-scale production. Puutalo Oy comprised 21 of Finland’s biggest companies in the wood industry that already had access to the necessary industrial production plants, forest reserves and networks for the transport of ready-made products. As a result, the collaboration could be launched quickly. The company had also gathered important experience from erecting 2,000 prefabricated wooden houses donated by the Government of Sweden, and the partner companies could make use of this competence in developing standardised house designs together. The houses were built of wooden panels, which enabled erecting the building in just a few days.

Nevertheless, for several years Puutalo Oy was not able to produce enough buildings to meet Finland’s needs for reconstruction, as the houses became a major export product already during the war. After the so-called Continuation war (1941–1944), Finland was on the losing side and was forced to pay war reparations to the Soviet Union. This included a large number of prefabricated buildings, around one hundred thousand. Part of these the Soviet Union acquired in barter transactions. Overall, the buildings were exported to more than 30 different nation-states, and these so-called “Finnish houses” can still be found on all populated continents.*

Despite the development of industrial construction, thousands of houses continued to be built by private individuals of plank wood. After the war, standard-project drawings by various non-profit operators were available to DIY builders. Utilising the drawings in acquiring wood and other construction materials was critical at a time when everything was in short supply. The drawings resulted in detached one-and-a-half storey houses with a balloon frame, in Finland nick-named as “front-line soldier’s house” (in Finnish rintamamiestalo). The reason why this building type became so widely spread has its origins in a legal act laid down in Finland after the end of the Second World War, under which plots of land were donated to veterans and their families for building their own homes.

Indeed, the Second World War had a major impact on Finnish wood construction and the organisation and steering of construction, and it continues to be reflected in the buildings still found in Finland today.

Woodloque

Similarly to the log houses with a solid frame, the wooden buildings of the 1940s and 1950s with a balloon frame or panels were constructed using a single material: wood-based materials such as sawdust and construction board were also used for thermal insulation. The use of a single material makes the structure easy to understand, maintain and fix.

Log construction never disappeared from Finland, either. It just fled to places where Finns spend time close to nature – the forests and Lapland. Even still, constructors most well-versed in traditions continue to fell trees using the old methods and use traditional tools in construction. At the turn of the millennium, this was even done at the scale of a church: a modern church was constructed in Kärsämäki solely using traditional wood construction techniques (Anssi Lassila, Kärsämäki Shingle Church, 2004).

More recently, massive wood has also made a comeback to cities; the reason is no longer that it is the only available material, but rather that a well-constructed house of massive wood has a long lifespan and is a healthy building. The fact that a wooden building will serve as a carbon stock throughout its life span is also considered one of its values. And at the end of its life cycle, the building can be taken apart, and the wood can be recycled or returned to its natural cycle.

But what is the epitome of Finland’s thousand-year-old log construction? That is naturally the Finnish smoke sauna!

* In 2021, Laura Berger, together with Philip Tidwell and Kristo Vesikansa, curated the exhibition New Standards, which told the story of Puutalo Oy. Produced by Archinfo, the exhibition was presented in the Finnish Pavilion at the 18th International Architecture Exhibition of La Biennale di Venezia. Since then, the exhibition has been on show in Finnish museums. The curators also published a book to complement the exhibition, New Standards – Timber Houses Ltd. 1940–1955 (Garret Publications 2021). More information is available online at newstandards.info.

Cover image: A peek at the courtyard of the Lyytikkälä farmhouse in Suomenniemi, whose main building was completed in 1867 and high storehouses in the 1840s and 1850s. photo: Livady Architects